_________________________________________________________________________________

Rapier

loom is a shuttleless weaving loom in which the filling yarn is carried through

the shed of warp yarns to the other side of the loom by finger like carriers

called rapiers. As in the projectile loom, a

stationary package of yarn

is used to supply the weft yarns in the rapier

machine. One end of a rapier, a rod or steel tape, carries the weft yarn. The

other end of the rapier is

Rapier

loom is a shuttleless weaving loom in which the filling yarn is carried through

the shed of warp yarns to the other side of the loom by finger like carriers

called rapiers. As in the projectile loom, a

stationary package of yarn

is used to supply the weft yarns in the rapier

machine. One end of a rapier, a rod or steel tape, carries the weft yarn. The

other end of the rapier is

connected to the control system .The rapier moves across the

width of the fabric, carrying the weft yarn across through the shed to the opposite side. The rapier is then retracted, leaving the new filling in place.

Rapier

loom is a shuttleless weaving loom in which the filling yarn is carried through

the shed of warp yarns to the other side of the loom by finger like carriers

called rapiers. As in the projectile loom, a

stationary package of yarn

Rapier

loom is a shuttleless weaving loom in which the filling yarn is carried through

the shed of warp yarns to the other side of the loom by finger like carriers

called rapiers. As in the projectile loom, a

stationary package of yarn connected to the control system .The rapier moves across the

width of the fabric, carrying the weft yarn across through the shed to the opposite side. The rapier is then retracted, leaving the new filling in place.

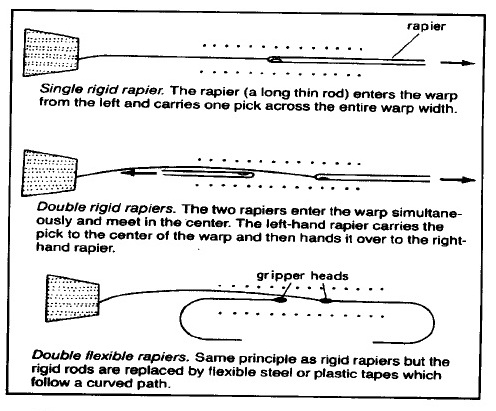

In some versions of the machine, two rapiers are used, each

half the width of the fabric in size. One rapier carries the yarn to the center

of the shed, where the opposing rapier picks up the yarn and carries it the

remainder of the way across the shed. A disadvantage of both these techniques

is the space required for the machine if a rigid rapier is used. The housing

for the rapiers must take up as much space as the width of the machine. To

overcome this problem, looms with flexible rapiers have been devised. The

flexible rapier can be coiled as it is withdrawn and will therefore require

less space. However, if the rapier is too stiff, it will not coil; if it is too

flexible, it will buckle. The double rapier is used more frequently than the

single rapier. Rigid and flexible rapier machines operate at speeds of up to

1,300 meters of weft per minute. These rapier looms are efficient. They operate

at speeds ranging from about 200 to 260 ppm at about the noise level of

projectile looms. They can produce a wide variety of fabrics ranging from

muslin to drapery and upholstery materials.

Newer rapier machines are built with two distinct weaving areas

for two separate fabrics. On such machines, one rapier picks up the yarn from

the center, between the two fabrics, and carries it across one weaving area; as

it finishes laying that pick, the opposite end of the rapier picks up another

yarn from the center, and the rapier moves in the other direction to lay a pick

for the second weaving area, on the other half of the machine. The above figure

shows the action on a single width of fabric for a single rigid rapier system,

a double rigid rapier system, and a double flexible rapier system .

Rapier machines weave more rapidly than most shuttle machines but more slowly than most projectile machines. An important advantage of rapier machines is their flexibility, which perm it’s the laying of picks of different colors. They also weave yarns of any type of fiber and can weave fabrics up to 110 inches in width without modification.

Rapier machines weave more rapidly than most shuttle machines but more slowly than most projectile machines. An important advantage of rapier machines is their flexibility, which perm it’s the laying of picks of different colors. They also weave yarns of any type of fiber and can weave fabrics up to 110 inches in width without modification.

A stationary package of yarn is used to supply the weft

yarns in the rapier machine. One end of a rapier, a rod or steel tape, carries

the weft yarn. The other end of the rapier is connected to the control system.

The rapier moves across the width of the fabric, carrying the weft yarn across

through the shed to the opposite side. The rapier is then retracted, leaving

the new pick in place.

In some versions of the loom, two rapiers are used,

each half the width of the fabric in size. One rapier carries the yarn to the

centre of the shed, where the opposing rapier picks up the yarn and carries it

the remainder of the way across the shed. The double rapier is used more

frequently than the single rapier due to its increases pick insertion speed and

ability to weave wider widths of fabric. The housing for the rapiers must take

up as much space as the width of the machine. To overcome this problem, looms

with flexible rapiers have been devised. The flexible rapier can be coiled as

it is withdrawn, therefore requiring less storage space. If, however, the

rapier is too stiff then it will not coil; If it is too flexible, it will

buckle. Rigid and flexible rapier machines operate at speeds operating at speeds

ranging from about 200 to 260 ppm, using up to 1300 meters of weft yarn every

minute. They have a noise level similar to that of modern projectile looms.

They can produce a wide variety of fabrics ranging from muslin to drapery and

upholstery materials.

Newer rapier machines are built with two distinct

weaving areas for two separate fabrics. On such machines, one rapier picks up

the yarn from the center, between the two fabrics, and carries it across one

weaving area; as it finishes laying that pick, the opposite end of the rapier

picks up another yarn from the center, and the rapier moves in the other

direction to lay a pick for the second weaving area, on the other half of the

machine. The above figure shows the action on a single width of fabric for a single

rigid rapier system, a double rigid rapier system, and a double flexible rapier

system .

Rapier machines weave more rapidly than most shuttle

machines but more slowly than most other projectile machines. An important

advantage of rapier machines is their flexibility, which permits the laying of

picks of different colors. They also weave yarns of any type of fiber and can

weave fabrics up to 110 inches in width without modification.

Thanks...

====> Always feel free to SHARE so that your friends can can know these

informations.

<> ♦♣♠ ♠♣♦ <>

Don’t forget to vote for this blog and

also feel free to rate the posts.

Thanks again. :)

__________________________-___________________________

No comments:

Post a Comment